1984 BMW 318i

This was the first non-Ford vehicle I have owned (actually it was in my wife's name). This was a gift from my mother-in-law to my wife. The car is in pristine condition since it had spent nearly all of its life in a garage in a desert climate, half in Richland Washington and the other half in Las Vegas. Most of the time it was not in the garage, my mother-in-law was behind the wheel.

I have an Airesearch turbo that I have had laying around in my garage for years. Up until now I never had a 4 cylinder car that was not already turbocharged. This car was begging for forced induction. The car drove and handled nice but it was no dragster. It has a 1.8L 4 cylinder engine (M10) with a power band from about 4000rpm to 6200rpm. The 3 speed automatic trans has a torque converter that stalls around 2000rpm with this engine in stock form. As you can imagine, pulling away from a stop was a chore for this powertrain.

Bone stock before any mods.

Bone stock before any mods.

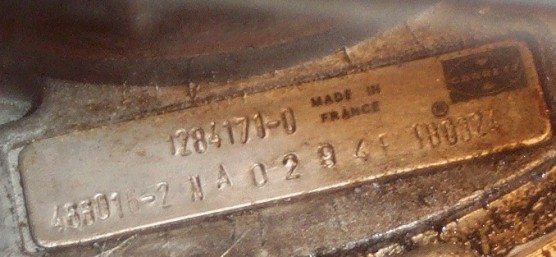

This is the tag on the turbo housing. It originally came from a mid-1980's BMW diesel turbo engine.

This is the tag on the turbo housing. It originally came from a mid-1980's BMW diesel turbo engine.

Since there are no turbo kits available for this car, I built the entire system from scratch. I built a tubular steel exhaust header to mate with the turbo. Luckily my turbo already had a wastegate and the housing has a standard 2.25" outlet making it easy to attach the exhaust system. The car has Bosch L-Jetronic fuel injection. This is an early analog system which is very basic. I had a 3" Bosch vane air meter (VAF) from one of my previous Thunderbird Turbo Coupes (2.3L intercooled turbo) which I modified by transplanting the circuit board and thermister from the BMW VAF (which was only 2.5"). I got a set of 24lb/h injectors from a 1996 Cobra and adjusted the VAF to match. That setup should supply enough fuel for about 185hp from this engine without using an FMU. The BMW runs higher fuel pressure though making them flow about 26lb/h. The injectors are standard Bosch units like those found an nearly all gasoline multiport fuel injected engines today. The original injectors were 14lb/h. The stock 1-7/8" system with a huge (and ugly) tin can muffler was too restrictive. I finally upgraded to a custom 2.5" system with a Walker DynoMax muffler. That made a huge difference.

Here is a picture of the engine in completely stock form. To date the modifications include:

- A 325E radiator

- 75C thermostat

- 1988 Mustang V8 in-tank turbine style high pressure fuel pump (NAPA# P74033, $98)

- Garrett/Airesearch T3 turbocharger with integral wastegate

- Custom made (by me) exhaust header with 1-5/8" primaries (later modified, a couple times)

- 1996 Mustang Cobra 24lb/h fuel injectors (14 Ohm (high) resistance, standard body)

- 1988 Thunderbird TurboCoupe 3" vane airflow meter housing with the factory BMW flow meter circuit board and thermister transplanted in.

- K&N 6" conical air filter (part# RE-0930)

- Air-to-air intercooler from 1986 Audi 5000s. I modified the inlet for this application.

- MSD Boost ignition retard (part# 5462) (required special wiring for the L-Jetronic)

- Custom 2.5" exhaust system with Walker DynoMax SuperTurbo muffler (part # WLK-17733 from Summit)

- Centerforce Dual Friction clutch set (part# DF018121). Found it at Performance International for $297. It has 90% more holding force.

- Added a stock 325i rear sway bar.

- Short throw shifter and carbon fiber (looking) shift knob.

- Autometer vacuum boost gauge (30"HG to 20psi)

- Blaubunkt MP3000 CD/MP3 stereo

- Pioneer speakers

These are a couple photos of the header I made for this turbo project. I bought the header flange (part# 130022338) to bolt to the head from Stahl Headers. The T3 turbine inlet flange (part# 30263) was purchased through Turbonetics. I bought 1-1/2" schedule 40 weld pipe and elbows from McMaster Carr. They have 2 different bend radiuses available, 1.5" (part# 43425K157) and 2.25" (part# 43425K151). They also have the 45 degree bends and of course the straight pipe. This tubing is 0.145" thick and is designed to be welded together. The inner diameter is actually 1.61" so it is really bigger than 1.5". This is the most common, and most commonly recommended, material for building turbo headers. I learned the hard way that regular header tubing will not work (click here to see it)!

The front 2 cylinders go into a single pipe. #3 goes up, makes

a 170 bend, then points directly into the turbo. #4 is extremely

short and makes a 90 degree bend. The header flange is welded to

the turbine flange. The turbo sits at a 25 degree angle to the head.

The front 2 cylinders go into a single pipe. #3 goes up, makes

a 170 bend, then points directly into the turbo. #4 is extremely

short and makes a 90 degree bend. The header flange is welded to

the turbine flange. The turbo sits at a 25 degree angle to the head.

Painted with 1500F paint.

Painted with 1500F paint.

There is almost no room to work with on the exhaust side of this engine. The engine has to be lifted just a bit to stuff the turbo and header in. Then the turbo and header are bolted loosely together, then the header bolted to the head. The intake side however, will enjoy improved access to the oil filter and throttle body since the factory air cleaner and vane air flow meter have been removed.

The turbo oil return line is made from corrugated stainless steel, much like the ones used on better OEM turbo applications. It is actually a natural gas appliance connection line available at any hardware store. I removed the lower oil pan, welded in the flared fitting that came with the stainless steel line, sealed it on the inside with high temp silicone (just to be sure) and re-installed the pan. This corrugated line will also cool the oil somewhat as it flows to the pan. The oil feed line is steel brake tubing with double flared ends. I tapped the turbo oil feed port and screwed a brass fitting into it. I drilled and tapped the oil filter adapter and installed a brass fitting in that end too. So both the oil feed and return are all metal with no hoses to leak or wear out.

The L-Jetronic injection control did not care for the MSD boost retard. I had to modify the wiring by moving the shielded wire (ECU pin 1) from a connection to the factory ignition module to the negative coil terminal. The problem was that L-Jetronic requires the primary ignition pattern to develop the injector pulse. Just switching the circuit ON and OFF was not enough. Once I rewired it, it worked fine. I am now running about 12psi boost and the engine has 9.3:1 compression. Detonation is a problem at times but I can easily dial it out with about 1/2 degree per psi retard.

The turbo to intercooler tube is made from 2" steel electrical conduit. The conduit has nice smooth bends and suits the need quite well. Since it is metal, it can also loose some heat here under full boost, although not much. The turbo inlet hose is a 3" rubber coated fabric with an integrated steel coil to maintain shape under vacuum. It is rated for up to 24" of vacuum and 28psi pressure. I ordered it through McMaster Carr (part# 56435K33). I also made a special piece of steel tube to connect between this hose and the turbo inlet. I welded a piece of steel tube into it to connect to the valve cover vent in place of the factory crankcase vent setup. This allows the crankcase to vent into the inlet of the turbo, keeping the closed crankcase system.

The intercooler was purchased from eBay for $50. It originally came from a 1986 Audi 5000S Turbo. I had to cut the inlet tube off and relocate it for this application. I had to remove the end cap to do this. I used a 2" expanding rubber freeze plug not only to fill the hole, but as an intercooler mount as well. I then used a 2" hole saw to cut the inlet hole where I needed it. I pop riveted the inlet tube into the new position and sealed it with high temp silicone on the inside. I made 4 steel clips to help retain the end cap after I reinstalled it.

The car drives much better although it still lacks power where it needed

it the most, at the bottom. Pulling away from a stop is still doggy

until it hits about 2500rpm, then the turbo gets busy and it makes up for

all the time you lost getting there. When the trans upshifts the

power is smooth and consistent. It used to fall off after upshifts

real bad. If this were a 5-speed car it would not be near the problem

but the automatic keeps the rpm down when pulling away from a stop.

Once you get going, the car feels a whole bunch crisper than before.

Just tip into the throttle and the boost comes right up and the car pulls

well. I can now pull hills at 1/3 throttle that used to take almost

full throttle. The 0-15 times did not change at all unless you powerbrake

it but from there up there is a big difference. The fun-to-drive

factor has gone up considerably. I would estimate (seat of the pants)

the peak power went up from 100HP stock to about 175HP but the torque is

much better and there is a bunch more midrange power. People who

have ridden in the car think this estimate could be low. It feels

like the power at 3500rpm has doubled. The power really starts to

hit hard at 4000rpm. At full throttle in 1st gear, the tires will

start to spin at about 3500rpm and the car will get sideways by the time

it hits 4500rpm. By then it is going about 30mph. It is hard

to control in the rain and will easily spin the tires up to 50mph.

Results prior to intercooler and with only 7psi boost: 0-60mph times

dropped from 11.4s (factory spec) to 7.4s (stopwatch/speedometer timing

method). 0-80mph times dropped from 20.9s to 12.4s, then 9.0s after

intercooler and exhaust. All runs were made at about 60F ambient

on the same road. I have 3psi available at 2000rpm and 6psi by 2300rpm.

I get about 11psi by 3000rpm. Since the intercooler and exhaust system

upgrade, the 0 to 60mph time dropped to 6.0 seconds (using a G-Tech Pro).

I have a horrible time getting traction (I have some cheap tires on it

now) so it is hard to get a good time. If I had good tires this could be

better. I can't use full throttle until about 10mph. I also

checked the quarter mile time with the G-Tech and it was 14.8 @ 97mph.

Using my own power program this would be about 142HP average at the wheels.

That would be around 190hp at the flywheel. Using the basic math

(power = weight*(mph/234.0)^3), the power estimate would be about 220hp

by speed or 190hp by quarter mile time (I have lousy starts with those

cheap, dinky tires). G-Tech reported peak power to be 184hp (rear wheel).

Here are some before and after videos. The before video is the

stock car. The after was taken just after intercooling but it

still had the auto trans. These videos are in Windows Media

format.

Before Turbo Video After

Turbo Video

12/20/2002 update: The trans gave up today. The fluid is black and stinky, 1st gear locks up the wheels, and 2nd gear makes a grinding noise. So much for the slushbox. Luckily, I acquired a complete drivetrain and all the parts I need to swap a 5-speed in, including the 5-speed. A co-worker totaled his '85 318i. I am concerned that the clutch will not live. I am having problems getting a performance clutch for this application. I imagine I will have this one toasted in short order and I will look into a better clutch then. Then the question is, will the trans hold up?

4/17/2003 update: Still no clutch so it can only support about 5psi boost, if I'm careful. Still, the car is MUCH more fun to drive now. I can actually hit 6psi boost by 2000rpm! Of course, it takes forever to get there at 2000rpm but I am still surprised it can do it. By 3000rpm the boost comes on quick. I know with a clutch the car will be faster than it was with the auto. I will get much better launches too.

5/10/2003 update: Just installed the new clutch. I have the 500

mile break-in to complete so I have left the wastegate set at 7psi for

now and I am driving it easy per the instructions. Can't wait to

get it on the dyno and check it with G-Tech.

5/23/2003 update: Finally made it to the dyno. The car

made 185HP and 196ft*lbs at the wheels. This translates to about

213HP and 225ft.lbs at the crank. I was running about 14psi for that

run but it was detonating a bit. We added some timing retard and

reduced boost and of course the power went down too. The engine also

was getting warm. The AF ratio is really bad between 3000rpm and

4000rpm. Ever since it was new the car has had a flat spot there

and now I see why. We shut it down at 5000rpm and it would have climbed

higher but the AF seemed lean and it was pinging. I was just using

Amoco 93 octane, no booster or additives. We also had a hard time

getting any decent airflow across the intercooler. It does not ping

normally. I think I need a programmable EFI system and larger injectors

next. As you can see from the AF ratio in the graph, the injectors

were all done. They were giving all they had. The actual power

exceeded my expectations for the fuel system. Luckily the higher

fuel pressure and extra margin in the injectors gave me a bit more than

I expected. I also was at a leaner mixture than I used to calculate

the injectors capabilities. Surprisingly, the dyno matched very well

with the G-Tech results above. G-Tech had reported 184hp peak at

the wheels back when I still had the auto trans. This car now smolders

the tires in 1st and 2nd gears, and it gives a healthy scratch shifting

into 3rd at over 50mph.

9/16/2003 update: I installed a short throw shifter from Bavarian Autosport, and a carbon fiber (looking) shift knob. Shifts much better. On the downside, the new Centerforce clutch is slipping. I suspect it got trans oil on it from the front trans seal. I am planning to replace the disc with a Clutchnet 6-puck and replace the trans seal this fall.

Return to main page

This is an old photo showing the intercooler plumbing. This was taken before the new header was built and several other improvements.

This is the most recent photo. The MSD control added. The cheezy washer bottle mounting is only temporary. I need to find a better location. Perhaps the battery will be relocated to the trunk to make room. The small brass valve near the coolant cap is a boost control. I can adjust boost pressure up by opening the valve. The vacuum switch you see on the firewall (connecting to the green line) makes the ECM think it is a full throttle anytime there is boost pressure.

Since I have completed this project, I have had several inquiries about building turbo headers, or the whole kit, for sale to other BMW owners. Custom systems like this are very labor intensive to develop. Much time is spent hand fabricating things. No time is spent documenting or planning for manufacturablilty since the plan was to build just one. It would be cost prohibitive for me to start developing kits based on this one car. The kit would cost more than the car is worth. I am more than happy to share detailed pictures and information about this project with anyone interesting in doing it themselves. The hardest part is building the header. I spent about a month (evenings and weekends) building the base system. I added the boost retard and intercooler later. For someone who likes to tinker, has a welder, metal cutting tools, and a good set of mechanics tools, this is a fun project worth doing. For someone who is looking for a weekend bolt-on kit however, this project is not for you.

BMW did offer a turbo option on some later 2002 models and I have heard of turbo kits for the 320i (although I don't know of any still available new). The manifold used in either of these should work on the 318i so if you could hunt one of them down you could be well on your way to making a system for your 318i.

Some have asked how much it cost. I started with the car, the turbocharger, the VAF sensor, and the set of injectors. All of these parts were just laying around in my garage so I can't include the cost of them in my estimate. Those items excluded, it was about $1000 (no labor).

Update 12/23/2003: This car sold to a friend of mine. He fixed

it back up and is driving it. He already owns a BMW motorcycle so this

will fit nicely in his garage. It had about 145k miles on it when I sold it.

Update 5-2008: This car sold again to another friend of mine. He installed Megasquirt, larger injectors, distributorless ignition, and a larger throttle body.

We tore the stock engine down at 148k miles and it showed almost no wear or stress. The cylinders still had the cross hatch and the bearings were all very tight. These engines are very stout!

Update 2-2011: This car sold again, to a different friend. He is finally putting

the turbo back on. We just finished welding up more modifications to the header.

Basically we finished replacing all the original thin wall tubing with weld

els.

Update 2017: I found this car on the internet here: http://www.wibimmers.com/board/index.php?/topic/4308-1984-318i-build/. It is now a drift car with a 6 cylinder engine and other major upgrades.